Behavior based safety observations (BBSO) are an integral part of behavior based safety programs, which aim to reduce the number of incidents by recognizing safe behavior, and eliminating the need for unsafe behavior. The general idea is that by creating safe work habits through observations, the number of incidents will decrease among workers.

The Construction Owners Association of Alberta (COAA) defines Behavior Based Safety (BBS) as "a process through which work groups can identify, measure and change their behaviors."

Human behavior is heavily influenced by what happens around us. By nature, people do what they see. However, it also means that it can be identified and measured by others, and changed according to different external influences.

Performing Behavior Based Safety Observations

BBSOs should be performed on a regular basis between workers. Workers must be selected and trained to act as observers, however, anyone can be observed.

In order to properly perform a BBSO, the observer must inform the observee that they are being watched. While it is common to assume that observation means that a worker will perform the task perfectly (which would be a good thing), habits and complacency can affect the outcome of the observation.

By acknowledging safe work behaviors in a positive way, workers are encouraged to repeat the behavior, and others are more likely to follow suit.

While BBSOs are performed among peers, it is important that the right people are selected to carry out the observations. When selecting observers within your company, ensure that candidates:

- Have experience with the task

- Be respected by their colleagues

- Believe in the BBS program

- Be able to provide positive feedback for safe behaviors

- Be able to provide coaching and discuss unsafe behavior

BBOs are intended to determine if workers are able to perform tasks safely and identify any hazards that could potentially cause harm. When performing observations, the observer will fill out a form or checklist that breaks the task down into smaller elements.

Once the observation has been completed, the observer will provide the worker with feedback and either positive reinforcement for safe behavior, or coaching and guidance regarding unsafe behavior. Any behaviors that present an immediate danger to the life and health of the worker, or to the environment, must be stopped immediately and a discussion between the observer and the worker regarding the matter should take place.

Keep in mind that the conversation should focus on why the behavior occurred and how it could be better executed, but should not be used as an opportunity to punish or chastise the worker. Encourage observers to record the reasons that the worker gives as to why they displayed unsafe behavior. It could stem from a lack of resources that has yet to be addressed (e.g. offering a wider selection of glove sizes if a worker complains of gloves being difficult to work with).

Creating an effective Behavior Based Safety program

The most difficult part of implementing a BBS program is to change everyone's way of thinking, from upper management to front line workers. It is human nature to look for flaws or negativity, however, the objective of BBS is to look for and praise positive behaviors.

In an article titled The Contributing Factors of Behavior Based Safety Failures, EHS identifies the most common reasons why BBS programs fail or are ineffective.

- Forced effort or involvement: If workers aren't passionate about the process, they will not be effective in executing it. It is important to motivate and make them believe in the process as opposed to ramming it down their throats.

- A "Gotcha" approach: Do not create an environment that suggests "us vs them" by spying on workers to "catch them in the act". Properly announcing the observation and praising good work will yield better results.

- Information used for discipline: The objective of BBS is to look for and praise positive behaviors. Instead of reprimanding workers for unsafe behavior, use unsafe observations as teaching moments, as well as an opportunity to look for issues within the task itself.

- Lack of action plans or visible success: Ensure that the safety team shares the data from the BBSOs and uses it to motivate the rest of the company. Employees can't be excited about a program if they don't see any results or changes being applied to their processes.

- Unfocused or misfocused efforts: Don't lose sight of the big picture. While you want to conduct regular BBSOs, you also want to conduct effective BBSOs. If your observers are more focused on meeting their quotas than creating a safer workplace, you won't get the results you are striving for.

- Retention and Internalization is an afterthought: If the entirety of your safety program depends solely on an external party, how will you retain it in times of hardship? Ensure that there are ways that you can retain and sustain your safety program if ever you can't afford your safety consultant or software.

- Expecting miracles: Humans are a product of their environment and experiences, and these shape every aspect of our lives. Changing mindsets and the frameworks people are used to will not happen overnight, so give your workers and BBS program time and room to grow before seeing a change.

- Stopping at behavior: Even though the goal of a BBS program is to stop unsafe behavior, it is important to acknowledge that these behaviors occurred for a reason. Engage workers in a conversation regarding their behavior and try to determine how you can best tackle the reasons why it happened in the first place.

No one plans on getting injured on the job and creating a positive safety culture for your workers can help drastically reduce the chances of anyone getting hurt. If your company is interested in following a Behavior Based Safety program, keep one thing in mind: BBS isn't "us vs them". BBS means everyone working together to keep each other safe.

Collecting Data

After implementing BBSOs for a while, you're going to find yourself with an abundance of rich and useful data! You can use this data in several ways to continue to perfect your safety program.

You may find that you'll gain insights into the reality of the safety at your organization. For example, if several workers are performing the exact same unsafe behavior, you've just put your finger on a gap in your safety program. The data can also assist you when reporting accidents, updating employee training, and other safety initiatives.

Behavior Observations Tool by Workhub

You may be asking yourself, where do I record these observations? How can I track progress effectively?

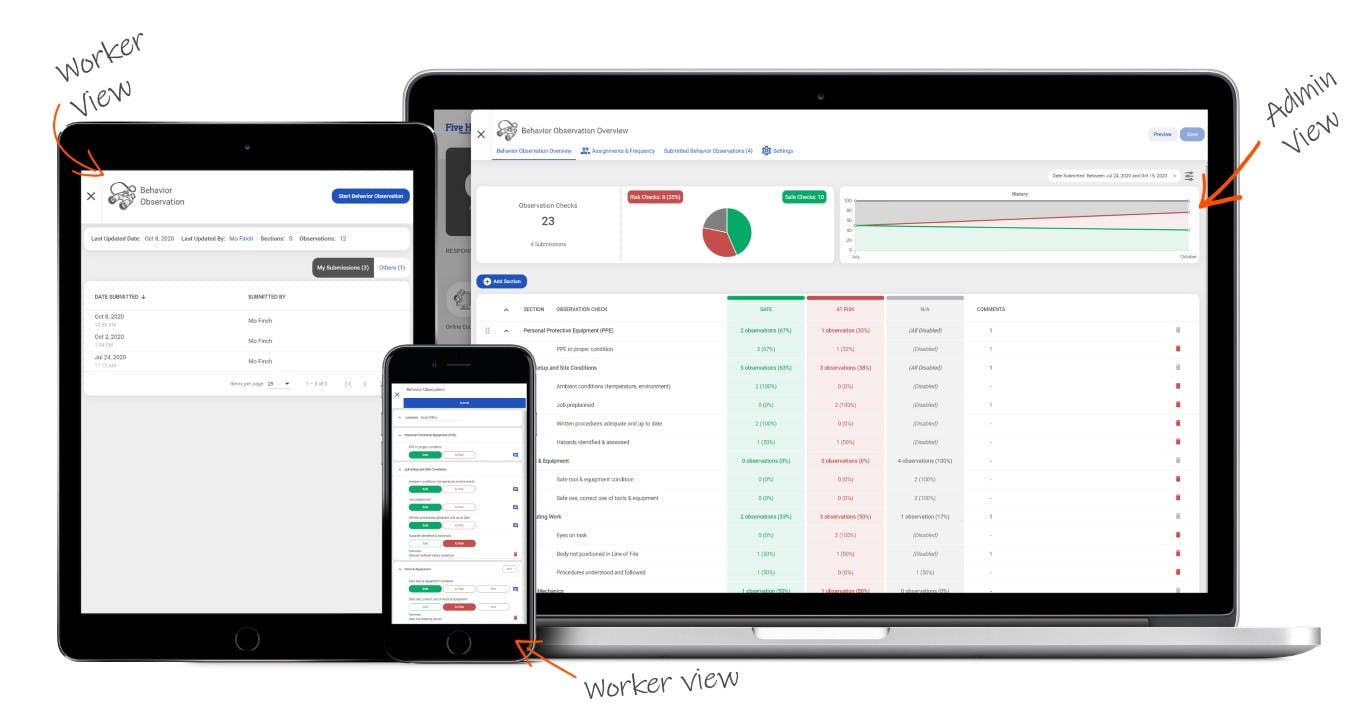

It may be a good idea to implement a safety management software that will provide you with a platform to record observations into and make tracking and analyzing data easier. Workhub’s Behavior Observations tool makes implementing BBSOs into your safety program extremely simple. The tool allows you to create and assign observations unique to your workplace for each of your workers and track both safe and unsafe behaviors. By centralizing your BBSO documents, it allows for seamless progress tracking of each worker and ensures consistent compliance in your workplace.

Watch our webinar on Behavior Based Safety Observations here for more info!

Workhub provides a complete health and safety compliance software that allows easy management of training, procedures, policies, inspections, and more, centralized in one easy-to-use hub.

Still have questions?

Let our knowledgeable sales team give you a full product tour and answer any specific questions you may have.

Workhub Internal